The problem

If one were to add the barrels of oil consumed per day of the world’s second largest oil consumer, China, the third largest consumer, Japan, the fourth largest consumer, India, and the fifth largest consumer, Russia, the United States would still consume more oil per day than these four countries combined (Nationmaster.com). Needless to say, the United States, and much of the world, is quite dependent on fossil fuels as a primary source of energy. Though fossil fuels are a reliable energy source, supply is not infinite and the by-products include greenhouse gasses which contribute to environmental alterations such as climate change. The United States Environmental Protection Agency (EPA) predicted in 2011, that if current patterns of emission continued, the temperature of the earth could from 2.0 to 11.5 degrees Fahrenheit above the temperatures of the 1990s (EPA, 2011).

The solution

It appears apparent that a solution to the unrestrained and undisciplined consumption of the earth’s natural resources is not only necessary but must also be implemented soon. This solution lies within renewable energy, which the United States Energy Information Administration (EIA) defines as any source of energy that can “regenerate and can be sustained indefinitely” (EIA, 2011). The source of renewable energy that we chose to pursue is wind energy, which has immense potential but only accounts for 11% of renewable energy sources utilized today. Additionally, wind energy is often harvested through large turbines which involve moving parts of both the device itself and the mechanical systems that harvest and condition the energy. Turbines also require higher wind velocities to generate electricity in effective amounts. We plan to design and construct a wind harvesting device that completely eliminates the need for moving parts, which require high maintenance, and aim to make the device efficient in areas with lower wind velocities by coupling the properties of piezoelectricity with the phenomenon of vortex induced vibrations (VIV).

Research

Hypothesis

If the components for each subsystem are experimentally determined based on highest performance, then the integrated product will be able to generate and store the maximum amount of energy.

The difference between the harvesting capability of the final product and the theoretical product will be statistically insignificant.

Phase I

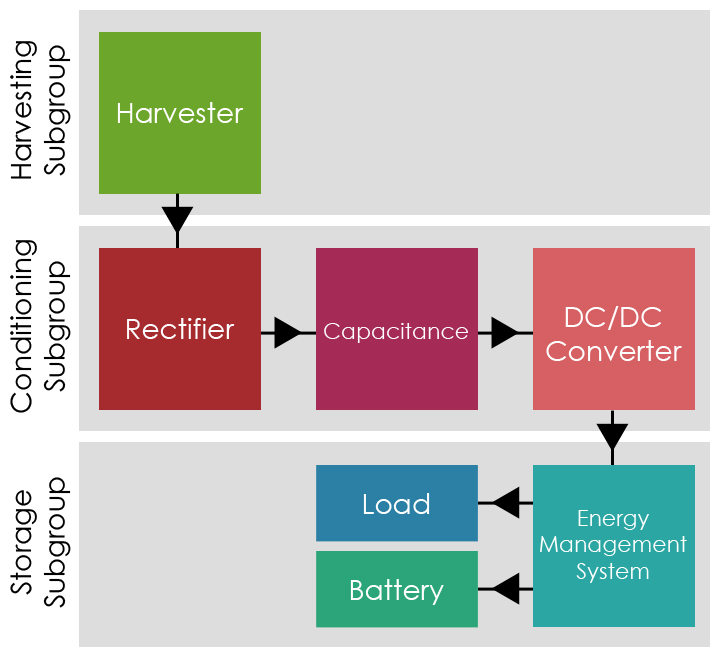

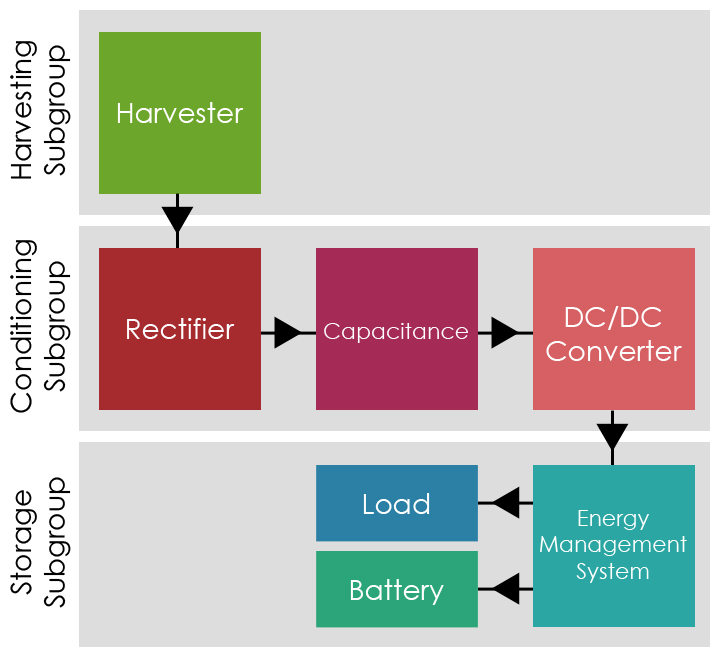

The harvesting subgroup includes Alden Grobicki, Chandan Kittur, Mark Lee, Edward Mulhern, and Mihir Patel. The group seeks to design and create the optimal piezoelectric wind harvesting device that will require a minimal amount of maintenance and moving parts. The subgroup's research will include establishing a range of wind speeds on campus, determining a piezoelectric material which produces the most energy output, simulating wind harvesting using a computer model, and creating a small scale device.

The members of the conditioning subgroup include Austin Baker, Ian Grissom, Kevin Keller, and Andrea Ng. The subgroup hopes to improve the power harvesting capabilities of the piezoelectric harvester by optimizing the conditioning circuit. To research the methods of producing stable DC output from the AC output of the harvester, the subgroup will examine the standard energy harvester (SEH) and the synchronized switch harvesting on inductors (SSHI). Other possible methods of increasing the harvested power involve self-tuning and impedance matching.

The storage subgroup consists of Kathryn Connolly, Lauren Dorsey, Daniel Konecki, Tim Lee, Boheng Ma. The goal of this subgroup is to determine the most appropriate and efficient storage device for a piezoelectric energy harvester. The storage system will be integrated into the overall design by a storage circuit, which will control the current flow to the battery or the load. The storage properties that are most important for the design include high energy density, long discharge time, long life cycle, low environmental impact, and no memory effect. These factors are important because the harvester cannot be expected to provide consistent or optimal energy levels regularly. In addition, the storage device may be expected to provide power to the light source for extended periods of time when the harvester is not generating energy simultaneously. Experimental testing will determine the optimal storage device for the performance of the system as a whole.

Subgroup Organization

Phase II

Phase II involves the integration of the separately developed subsystems into a functional prototype. Once all of the subsystems are integrated into all possible combinations, the team will calculate the theoretical efficiencies of every combination. The efficiency of the full prototype will be calculated from the available wind power and battery. This experimental value will then be compared to theoretical efficiency. The three combinations of experimental groups with the highest theoretical efficiencies will be chosen for further experimentation.

The second part of Phase II will involve constructing the best three combinations and testing them in the wind tunnel. These prototypes will be tested on the range of wind velocities determined in Phase I to simulate typical wind conditions on the UMD campus.

The final part of Phase II will involve creating a full-sized version of the most efficient prototype and testing the device in the field.