|

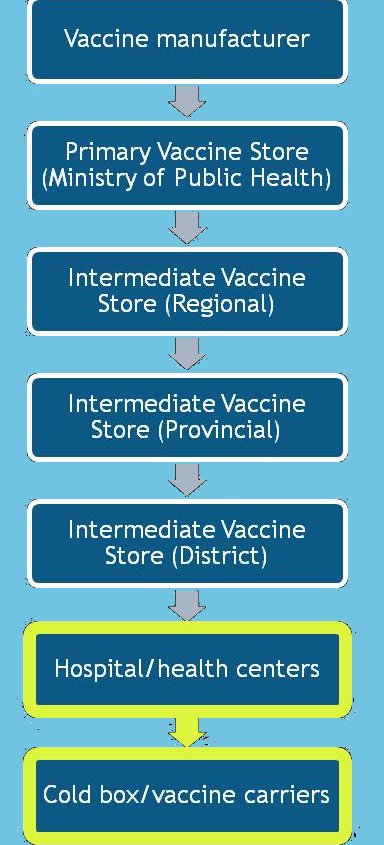

The steps of the cold chain The steps of the cold chain The vaccine delivery system, called the cold chain, starts with large shipments of up to 1.5 million vials of vaccines that are shipped or flown, in refrigerated containers or compartments, from the manufacturer to the Ministry of Health of the country that placed the order. The vaccines are stored in a cold room at the airport until a refrigerated truck delivers them to the Ministry of Public Health, or a primary vaccine store. Vaccines are delivered quarterly from the Ministry of Health to regional centers, and from there are delivered monthly to provincial health centers. From the provincial health centers, vaccines are delivered as needed to local health centers and outreach clinics. Refrigerated trucks are used in areas with large regional populations; while elsewhere the entire system is comprised of cold boxes, which will not be able to meet the estimated volume of vaccines. The entire delivery process, depending on demand, ranges from one to three months.

Problems in the cold chain result directly in the decreased potency of vaccines. It is estimated that because of problems in the cold chain 70% of vaccines are rendered impotent. This results from freezing during transportation, unreliable energy at local level facilities, and a dearth of long-term storage at local facilities. Due to these holes in the cold chain, current immunization programs such as the World Health Organization's Extended Programs on Immunization are not as efficient as they could be.

|